Automated mooring substantially cuts vessel emissions: report

A new report demonstrates how automated mooring system (AMS) makes substantial reductions in CO2 emissions produced by ferries during mooring operations.

A new report demonstrates how automated mooring system (AMS) makes substantial reductions in CO2 emissions produced by ferries during mooring operations.

As ports, shipping lines, and authorities in China strive to reduce emissions from shipping, our innovative shore power technologies are playing a key role in delivering substantive change.

Global engineering group Cavotec has officially opened its new world-class production facility in Milan, which is set to ensure the Group’s manufacturing and supply chain excellence in the years ahead.

Global engineering group Cavotec has launched its new tagline and strategic direction statement. Two defining elements of the Cavotec identity that reflect the Group’s key role as a trusted industrial partner for a global customer base, and its intent to maximise future growth potential.

Cavotec is set to revolutionise the operation of e-vessels by delivering and maintaining its automated, unmanned, mooring system MoorMaster™ for e-ferry ports across Norway. With these orders, MoorMaster™ is now the leading technology to safely and efficiently moor e-vessels, a segment set for rapid growth.

Our MoorMaster™ automated mooring technology has been included in the 2018 UN Global Opportunity Report that highlights how "innovative technologies are making genuine progress towards a more sustainable world."

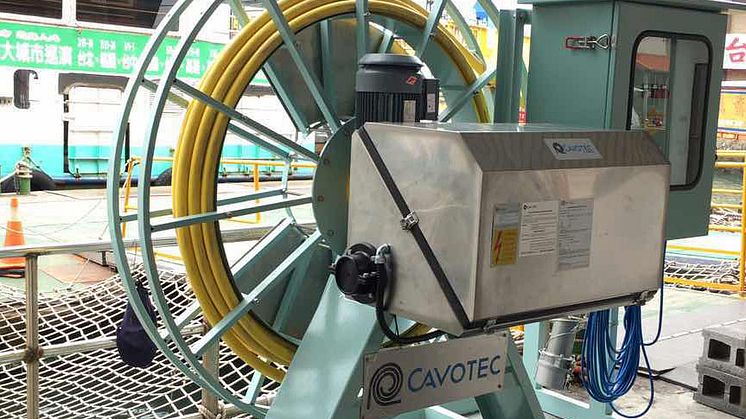

Konecranes has selected Cavotec to supply advanced cable reel technologies for two electrically powered Boxhunter Rubber Tyred Gantry (RTG) cranes at an application in Paraguay. The cranes are the latest generation of Konecranes lightweight RTG cranes, and are set to reduce environmental impact and improve operational efficiency at the port.

Working closely with mining group Atlas Copco, Cavotec has developed an innovative Human Operator Interface (HOI) system, incorporating long-range wireless communication, for operators of rugged loader vehicles used in mining applications deep underground. The solution, which first entered service in 2016, has generated substantial safety and efficiency gains at a mining application in Russia.

Our innovative charging technologies have connected Asia’s first e-ferry to electrical power, eliminating emissions and dramatically reducing operating costs, and highlighting Cavotec’s leading position in this increasingly important segment.

Cavotec engineers have once again manufactured cable reels that set new standards in operational performance with reels that provide electrical power for ship-to-shore (STS) container cranes that boast the highest lifting distance of any STS cranes anywhere in the world today.

We'd like to thank all our followers, customers, partners, and suppliers for 2017, and wish you all the best for 2018.

We’re proud to support heavy-duty haulage specialist Goldhofer to move some of the world’s heaviest objects. Over the past 10 years, Cavotec Radio Remote Control (RRC) solutions have helped transport NASA’s Space Shuttle Endeavour, shift a vast bridge section on the French island of La Reunion, and carry segments of oil rigs, building structures, and large tanks and reservoirs.