Blog post -

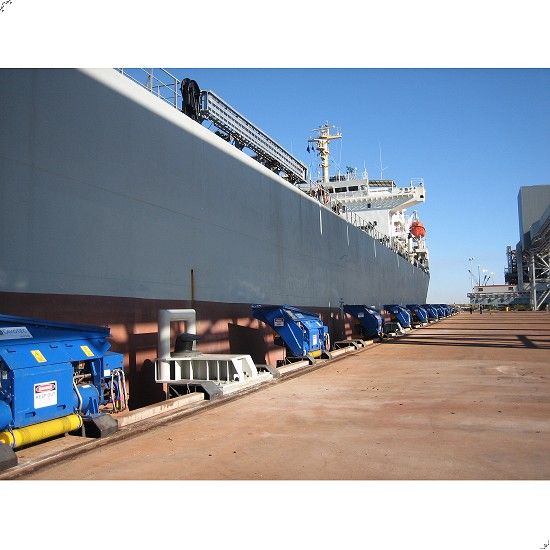

Port Hedland MoorMaster™ Update

MoorMaster™ is a vacuum-based automated mooring technology that eliminates the need for conventional mooring lines. Remote controlled vacuum pads recessed in, or mounted on, the quayside, moor and release vessels in seconds. The system offers improved safety, infrastructure savings, improved turn-around times and reductions in emissions.

The local North West Telegraph newspaper covered the commissioning of the MoorMaster™ units at Port Hedland.

The PHPA’s MoorMaster™ units are built to withstand the especially harsh operating environment at the port. Not only will the units face abrasive iron ore dust and falling rocks, during cyclone season, which runs from November to the end of February, seawater spray and winds will regularly blast the systems at speeds of up to 200 mph (320 kph).

Port Hedland’s iron ore facility is particularly exposed: situated directly on the mouth of a tidal inflow area, with tides ranging up to five metres. While the systems will not be required to moor vessels during cyclones, the systems will be able to compensate for the port’s exceptional changes in tide levels.

In a similar application, we are currently installing eight MoorMaster™ units forHammersley Iron Pty Ltd, a subsidiary of Anglo-Australian mining group Rio Tinto, at the Port of Dampier, also in Western Australia. The units will serve the Dampier Fuel Wharf, located on the eastern end of the Parker Point ore wharf. Each unit will have a capacity of 20 tonnes, and will complete vessel mooring in less than 30 seconds and disengage in less than 10 seconds.

MoorMaster™ is also in use at Canada’s St. Lawrence Seaway, on RoRo ferry routes run by Searoad Shipping Australia and Toll in New Zealand, at the APM Terminals container facility at the Port of Salalah in Oman, and on three high frequency fast ferry routes in Denmark, operated by Nordic Ferry Services A/S.